Detail

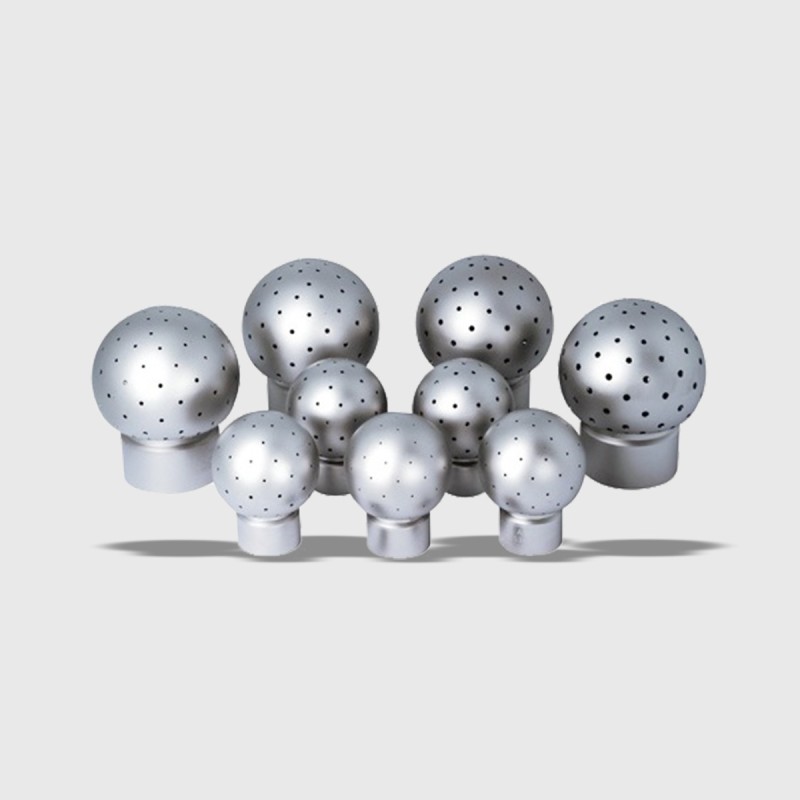

360° Routed Tank Cleaning Nozzle: Gear given tank cleaning machine for the largest tanks and most difficult applications, this gear driven tank washing machine is our most powerful.

360° Routed Tank Cleaning Nozzle Features And Benefits

360° routed nozzles rotate in multiple axes to provide complete 360° coverage of entire tank every 45 revolutions.

Simple self-cleaning, flow-through design

Easy to maintain – no internal reduction gears

Can be permanently mounted or moved from tank to tank

Very high cleaning performance already at low pressures

Driven and lubricated by the cleaning fluid

Systematically cleans the entire tank interior (360°)

Robust, low-maintenance stainless steel construction

The standard machine configuration uses two or four nozzles to blast the tank walls and rinse all surfaces. In operation, the unit has to run for the cycle time between 7 and 41 min depending on type and pressure. This ensures full cleaning. For extremely difficult applications the cleaning time might have to be extended.

Ideal for:

Max. Tank diameter for: Rinsing: 24 m, cleaning: 15 m

Operating pressures: 2 - 5 bar

Temperature range: 2 - 60 °C

Installation: Operating in every direction is possible

Materials: Stainless steel AISI 316L. Gear components made of PTFE and carbon fiber

Weight: approx. 7, 5 kg

Connection: Female thread 1 1/2 BSPP

Ideal for:

Brew kettles

Chemical processing tanks

Dairy vessels

Food processing vats

Spray dryers

Tanker trucks

Chemical processing

Food processing

Pharmaceutical tanks

Pulp and paper